The core function of an air-to-air heat exchanger is to transfer the residual heat carried in the exhaust air (indoor exhaust air) to the fresh air (outdoor intake air) through heat exchange, without directly mixing the two airflows. The entire process is based on the principles of heat conduction and energy conservation, as follows:

Exhaust waste heat capture:

The air expelled indoors (exhaust) usually contains a high amount of heat (warm air in winter and cold air in summer), which would otherwise dissipate directly to the outside.

The exhaust air flows through one side of the heat exchanger, transferring heat to the heat conducting material of the heat exchanger.

Heat transfer:

Air to air heat exchangers are usually composed of metal plates, tube bundles, or heat pipes, which have good thermal conductivity.

Fresh air (air introduced from outside) flows through the other side of the heat exchanger, indirectly contacting the heat on the exhaust side, and absorbing heat through the wall of the heat exchanger.

In winter, fresh air is preheated; In summer, the fresh air is pre cooled (if the exhaust air is air conditioning cold air).

Energy recovery and conservation:

By preheating or pre cooling fresh air, the energy consumption of subsequent heating or cooling equipment is reduced. For example, in winter, the outdoor temperature may be 0 ° C, with an exhaust temperature of 20 ° C. After passing through a heat exchanger, the fresh air temperature may rise to 15 ° C. This way, the heating system only needs to heat the fresh air from 15 ° C to the target temperature, rather than starting from 0 ° C.

Airflow isolation:

Exhaust and fresh air flow through different channels in the heat exchanger to avoid cross contamination and ensure indoor air quality.

technological process

Exhaust collection: indoor exhaust gas is guided to the air-to-air heat exchanger through a ventilation system (such as an exhaust fan).

Fresh air introduction: Outdoor fresh air enters the other side of the heat exchanger through the fresh air duct.

Heat exchange: Inside the heat exchanger, exhaust and fresh air exchange heat in isolated channels.

Fresh air treatment: Preheated (or pre cooled) fresh air enters the air conditioning system or is directly sent into the room, and the temperature or humidity is further adjusted as needed.

Exhaust emission: After completing heat exchange, the exhaust temperature decreases and is finally discharged outdoors.

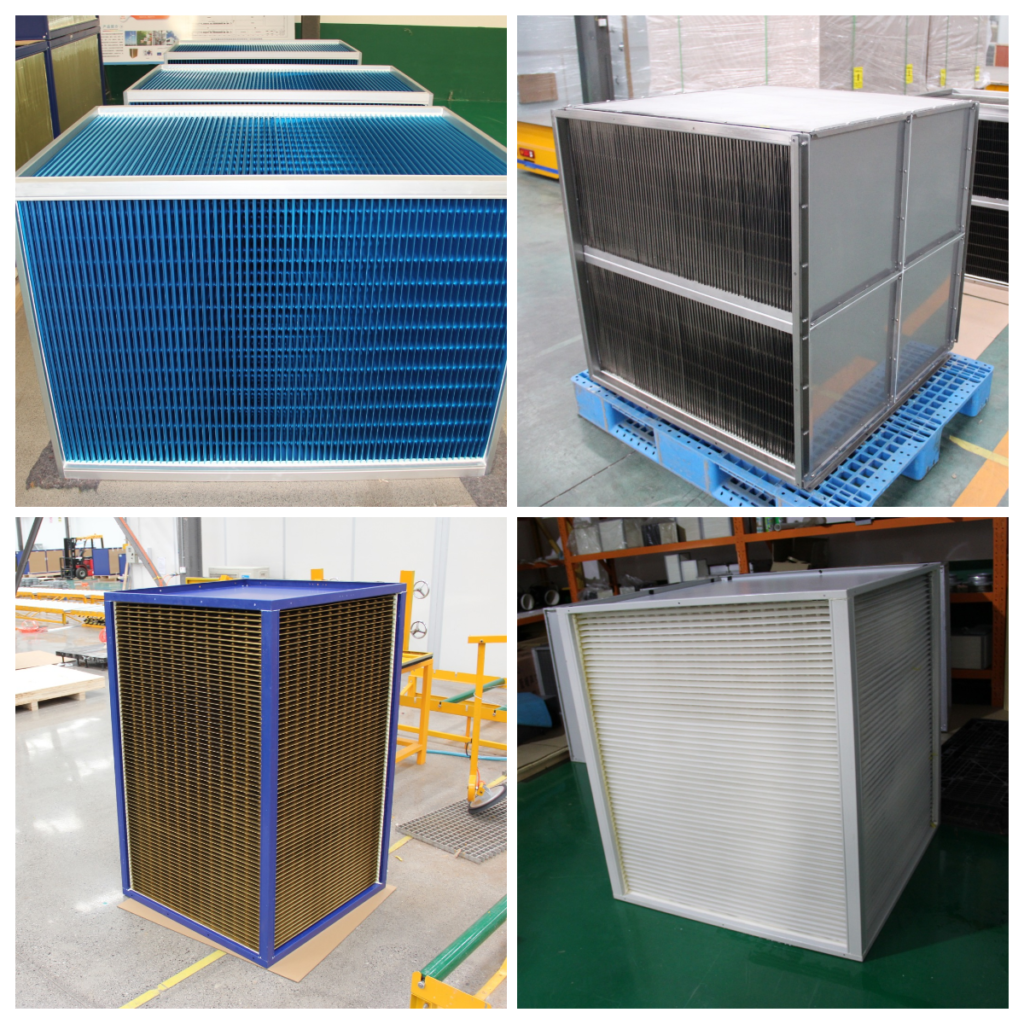

Types of air-to-air heat exchangers

Plate heat exchanger: composed of multiple layers of thin plates, with exhaust and fresh air flowing in opposite or intersecting directions in adjacent channels, resulting in high efficiency.

Wheel heat exchanger: using rotating heat wheels to absorb exhaust heat and transfer it to fresh air, suitable for high air volume systems.

Heat pipe heat exchanger: It utilizes the evaporation and condensation of the working fluid inside the heat pipe to transfer heat, and is suitable for scenarios with large temperature differences.

advantage

Energy saving: Recovering 70% -90% of exhaust waste heat, significantly reducing heating or cooling energy consumption.

Environmental Protection: Reduce energy consumption and lower carbon emissions.

Enhance comfort: Avoid direct introduction of cold or hot fresh air and improve indoor environment.