Indirect evaporative cooling (IEC) units are increasingly used in electrical panel rooms, control rooms, and equipment enclosures to provide energy-efficient cooling without introducing additional humidity. These rooms typically house sensitive electrical and electronic equipment that generates heat during operation and requires a controlled temperature environment for reliable functioning.

Application of Indirect Evaporative Cooling Units in Panel Rooms

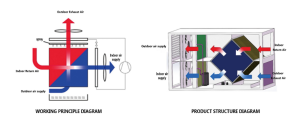

How It Works

An indirect evaporative cooling unit cools the air without direct contact between water and the air inside the panel room. Instead, it uses a heat exchanger to transfer heat from the warm air inside the room to a secondary air stream that is cooled by evaporation. This process ensures that:

-

No moisture enters the panel room.

-

The internal air remains clean and dry.

-

Energy consumption is significantly lower than traditional mechanical refrigeration.

Benefits in Panel Room Applications

-

Moisture-Free Cooling:

Since no direct contact with water occurs, sensitive electrical components are safe from condensation and corrosion risks.

-

Energy Efficiency:

Compared to traditional air conditioning systems, IEC units consume less power, making them ideal for continuous operation in industrial settings.

-

Reduced Maintenance:

With fewer mechanical components and no refrigeration cycle, the system is simple to maintain and has a longer operational life.

-

Improved Reliability:

Maintaining a stable and cool environment helps prolong the life of control panels and reduces the risk of equipment failure caused by overheating.

-

Environmentally Friendly:

No refrigerants are used, reducing the system’s environmental impact.

Typical Applications

-

Electrical panel rooms in factories

-

Server and network control cabinets

-

Inverter or PLC (programmable logic controller) rooms

-

Outdoor telecom enclosures

-

Substation control rooms