Устройства косвенного испарительного охлаждения (КИО) все чаще используются в электрические щитовые комнаты, диспетчерские, и корпуса оборудования Для обеспечения энергоэффективного охлаждения без повышения влажности. В таких помещениях обычно размещается чувствительное электрическое и электронное оборудование, которое выделяет тепло во время работы и для надёжной работы которого требуется контролируемая температура.

Применение установок косвенного испарительного охлаждения в панельных помещениях

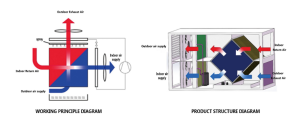

Как это работает

Система косвенного испарительного охлаждения охлаждает воздух без прямого контакта воды с воздухом в помещении. Вместо этого используется теплообменник для передачи тепла от тёплого воздуха внутри помещения к вторичному потоку воздуха, охлаждаемому за счёт испарения. Этот процесс обеспечивает:

-

Нет влаги входит в комнату управления.

-

The воздух внутри остается чистым и сухим.

-

Потребление энергии значительно ниже чем традиционное механическое охлаждение.

Преимущества применения в распределительных шкафах

-

Охлаждение без влаги:

Поскольку прямого контакта с водой не происходит, чувствительные электрические компоненты защищены от риска образования конденсата и коррозии.

-

Энергоэффективность:

По сравнению с традиционными системами кондиционирования воздуха блоки IEC потребляют меньше электроэнергии, что делает их идеальными для непрерывной работы в промышленных условиях.

-

Сокращение затрат на техническое обслуживание:

Благодаря меньшему количеству механических компонентов и отсутствию холодильного цикла система проста в обслуживании и имеет более длительный срок эксплуатации.

-

Повышенная надежность:

Поддержание стабильной и прохладной среды помогает продлить срок службы панелей управления и снижает риск выхода оборудования из строя из-за перегрева.

-

Экологически чистый:

Хладагенты не используются, что снижает воздействие системы на окружающую среду.

Типичные области применения

-

Электрощитовые на заводах

-

Шкафы управления серверами и сетями

-

Комнаты с инверторами или ПЛК (программируемым логическим контроллером)

-

Уличные телекоммуникационные корпуса

-

диспетчерские подстанции